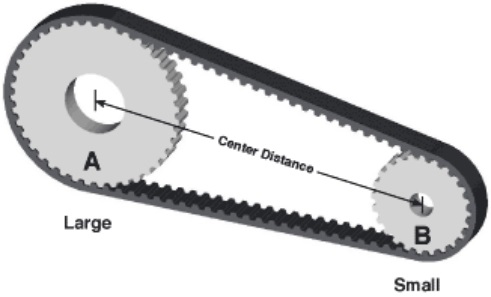

BELT LENGTH CALCULATOR

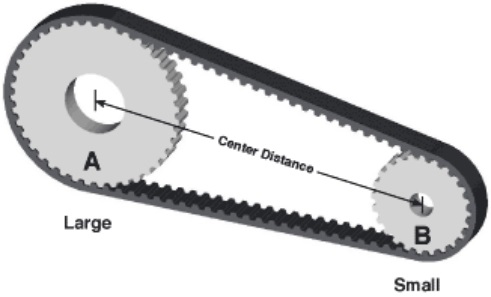

The system represented consists of an electric motor and a gearbox. The calculator is designed to obtain the technical specifications at the output of the gearbox. To use this calculation tool, input data as detailed in the following protocol:

MOTOR:

From these inputs, the calculator will generate the Nominal Torque, which will display the nominal torque the motor can develop based on the input rotational speed and power.

GEARBOX:

Input information pertaining to the gearbox that will be connected to the motor.

OUTPUT:

The number of poles determines the nominal rotation velocity, when motor is connected by contactor.

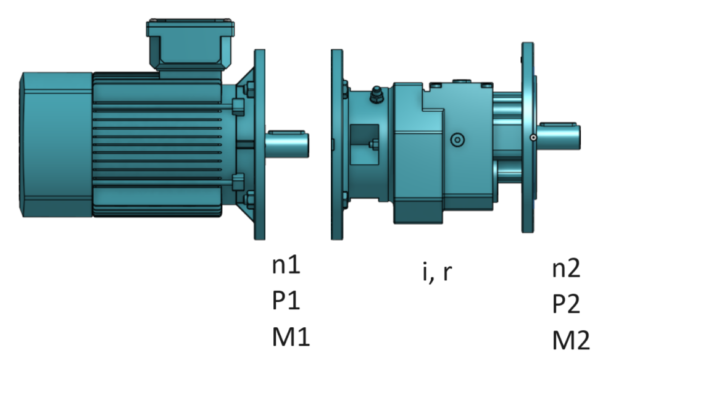

ISO 606

DIN 8187

ISO 606

DIN 8187

Murtfeld – Tensioning systems (spann box)

Groeneveld Lubrication systems by Timken

Timken – Standard Chain Lubrication Systems (Brochure)

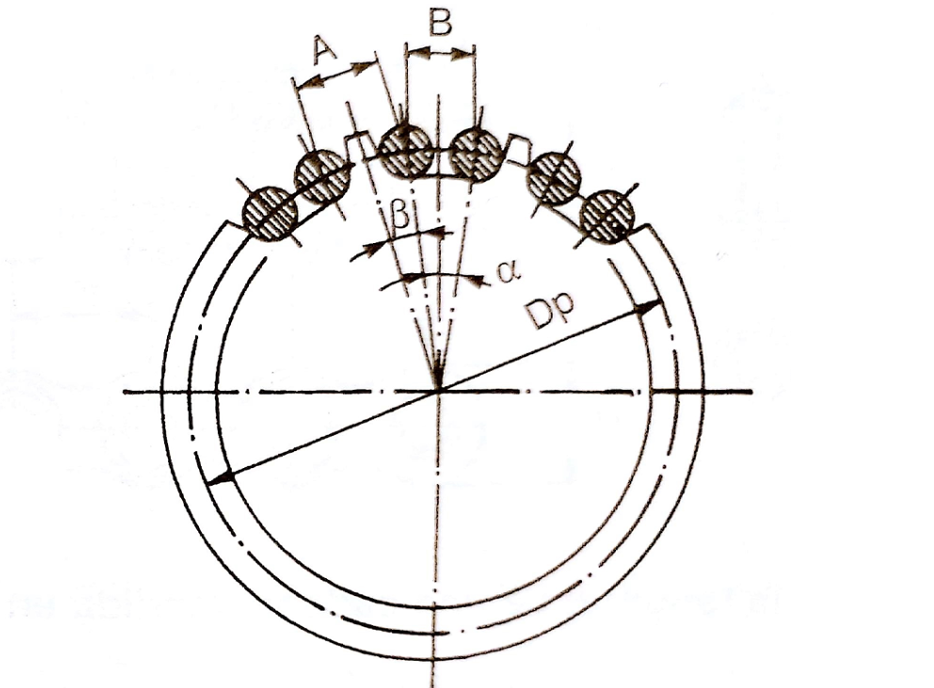

The calculator provide the Primitive Diameter of sprockets introducing the Chain Pitch and the Number ot Tooth.

Emissivity coefficient is a value between 0 to 1, that measures the radiation compared with a emissivity of an ideal black body evaluated with Stefan-Boltzmann Law.

Metric prefixes precedes a basic unit of measure to indicate a multiple or a fraction of the basic unit.

The commonly measures that uses prefixes are energy, length, mass, time and angles, volume, and some non-metric units (byte, decibel, pound, …).

| Vickers HV | Rockwell E Hre | Rockwell C Hrc | Examples |

|---|---|---|---|

| 125 | 68.5 | - | |

| 127 | 70.0 | - | |

| 130 | 71.0 | - | |

| 132 | 72.0 | - | |

| 135 | 73.0 | - | |

| 137 | 74.0 | - | |

| 140 | 75.0 | - | |

| 143 | 76.5 | - | |

| 147 | 77.5 | - | |

| 150 | 78.5 | - | |

| 153 | 79.5 | - | |

| 156 | 81.0 | - | |

| 159 | 82.0 | - | |

| 163 | 83.0 | - | |

| 178 | 87.0 | - | |

| 183 | 88.0 | - | |

| 188 | 89.0 | - | |

| 192 | 90.0 | - | |

| 196 | 90.5 | - | |

| 202 | 91.5 | - | |

| 207 | 93.0 | - | |

| 212 | 93.5 | - | |

| 218 | 94.5 | - | |

| 222 | 95.5 | - | |

| 228 | 96.5 | - | |

| 234 | 97.5 | 19.0 | |

| 241 | 98.0 | 20.5 | |

| 247 | 99.0 | 21.6 | |

| 253 | 100.0 | 22.8 | |

| 261 | 101.0 | 24.1 | |

| 269 | - | 25.4 | |

| 276 | - | 26.5 | |

| 284 | - | 27.6 | |

| 292 | - | 28.7 | |

| 301 | - | 29.9 | |

| 310 | - | 31.0 | |

| 319 | - | 32.1 | |

| 329 | - | 33.2 | |

| 339 | - | 34.3 | |

| 350 | - | 35.4 | |

| 360 | - | 36.6 | |

| 372 | - | 37.8 | |

| 383 | - | 39.1 | |

| 396 | - | 40.4 | |

| 410 | - | 41.8 | |

| 425 | - | 43.1 | |

| 440 | - | 44.5 | |

| 457 | - | 45.8 | |

| 474 | - | 47.2 | |

| 495 | - | 48.7 | |

| 516 | - | 50.3 | |

| 535 | - | 51.4 | |

| 553 | - | 52.5 | |

| 560 | - | 53.0 | |

| 577 | - | 54.0 | |

| 595 | - | 55.0 | |

| 613 | - | 56.0 | |

| 633 | - | 57.0 | |

| 653 | - | 58.0 | |

| 674 | - | 59.0 | |

| 697 | - | 60.0 | |

| 720 | - | 61.0 | |

| 746 | - | 62.0 | |

| 772 | - | 63.0 | |

| 800 | - | 64.0 | |

| 832 | - | 65.0 | |

| - | - | - |

Conversion from one hardness scale to another is only an approximate process. Differents types of hardness tests do not all measure the same combination of material properties. Because of the wide range of variation among different materials, it is not possible to state confidence limits for the errors in using a conversion chart.