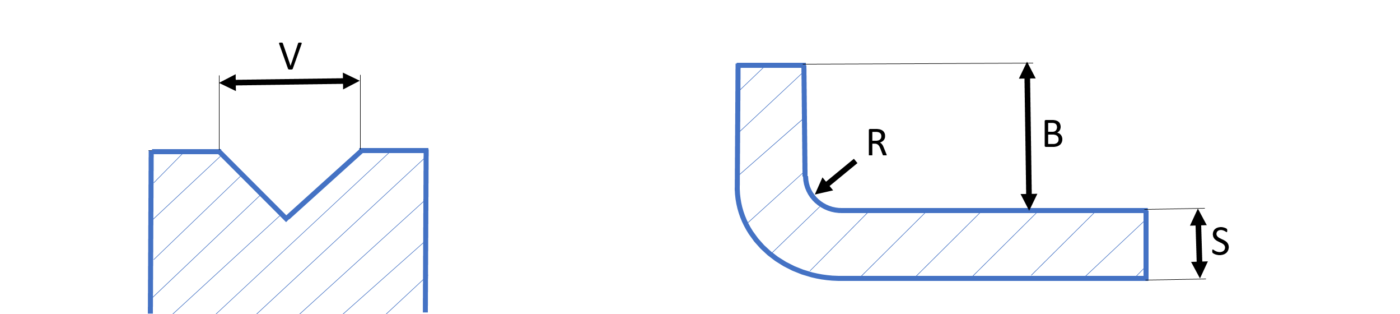

Recommended radius and flap in sheet bending

The table shows the minimum, optimus and maximum recommended punch widht (V), radius (R) and flap (B) for bending a steel sheet. This values could be different depending on the bending machine used for bending the sheet, but we can take them as reference values.