Slings for machinery lifting

The minimal Safety factor must be at least equal to:

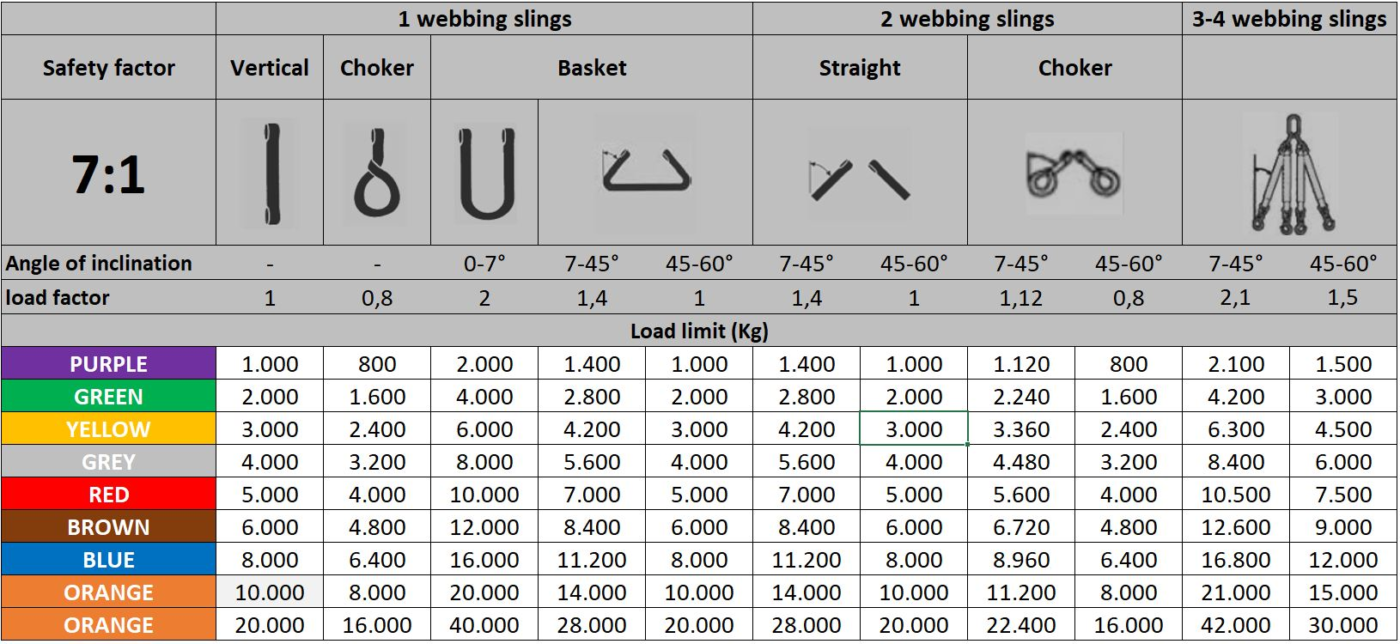

7:1 for webbing and round slings

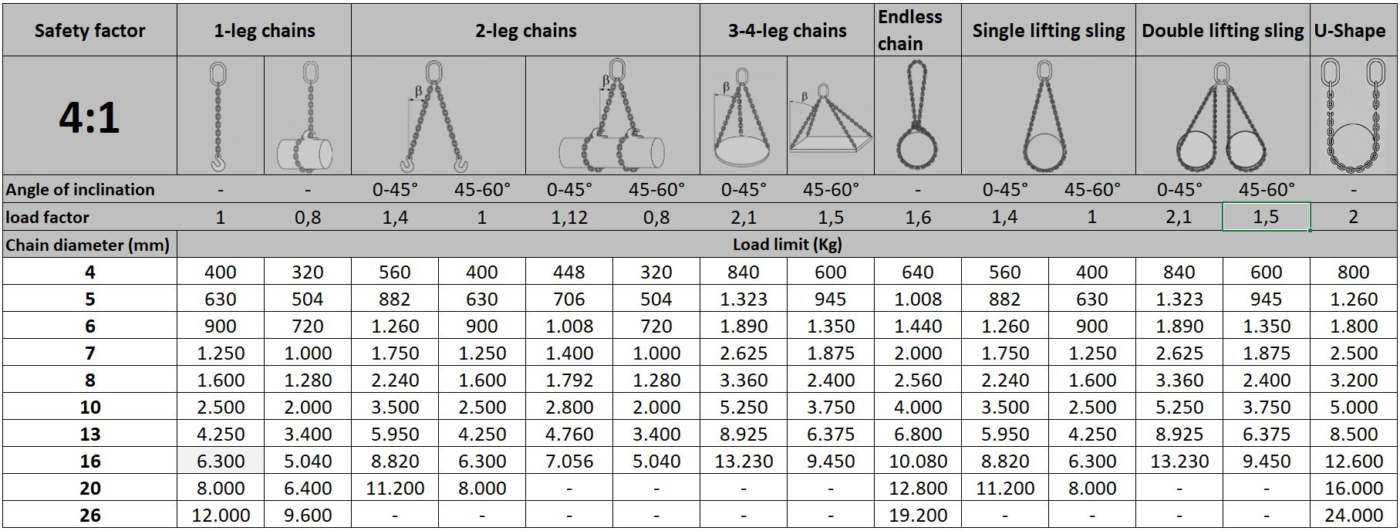

4:1 for accessories made of steel

5:1 for the remaining components

Recommendations of use:

- Never slide slings under a load. Never leave a load laying on a sling.

- Never knot slings or never use twisted slings.

- Protect from any sharp edges.

- Never use knotted, cut or damaged slings without tags.

- Check the weight of the load. Never overload.

- Use slings in arrange of temperature -40°C to +100°C.

- Reference to the standards: EN 1492-1, EN 1492-2, DIN 61360, CEN Norm.

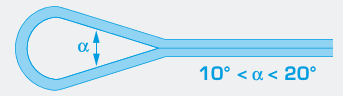

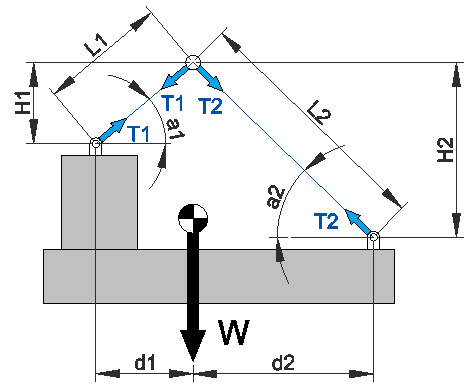

Eye opening angle

The minimum length for the eyes is fixed by standard EN 1492-1 to 3 times the width of the sling for widths up to 150mm; 2,5 times for width above 150mm. These lengths have been fixed to respect an angle usage between 10° to 20° when using the slings. An excessive eye opening angle will open the sling and a small eye opening angle will generate a bending stress at the lifting axis.