Bolt axial force vs torque

The torque required to tighten the bolt:

Where:

T: Torque (N.m)

K: Torque coefficient

F: Axial preload force (N)

d: Nominal bolt diameter (mm)

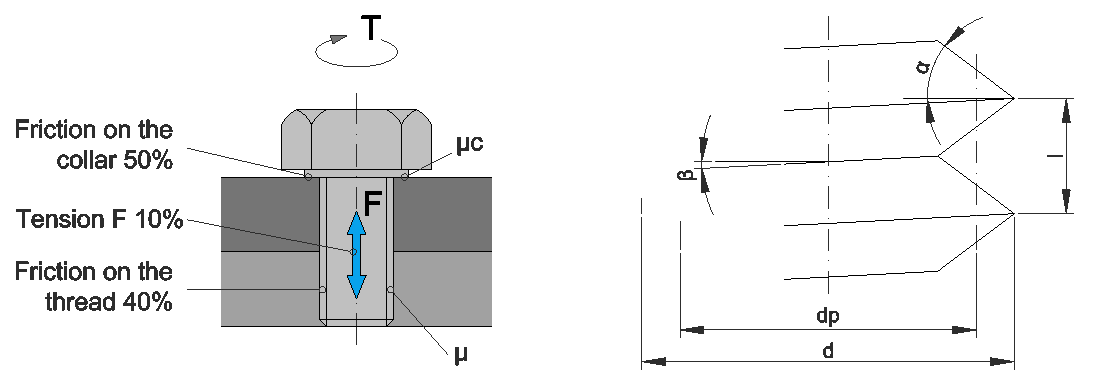

The torque coefficient:

Where:

l: Lead (mm)

α: Half angle of the screw thread (°)

d: Nominal bolt diameter (mm)

µ: Thread friction coefficient

µc: Collar friction coefficient

Common torque coefficient values for µ=µc=0.15:

| Bolt condition | K |

| Non plated black finish steel bolts | 0.3 |

| Mild steel bolts | 0.2 |

| Zinc plated steel bolts | 0.2 |

| Lubricated steel bolts | 0.18 |

| Cadmium plated steel bolts | 0.16 |

| With bowman anti-seize | 0.12 |

| With bowman-grip nuts | 0.09 |

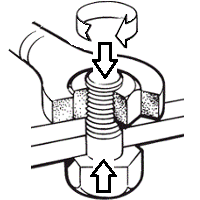

It is estimated that roughly 90% of the input energy is lost in overcoming the mating friction under the head (collar) and between the thread or nut and its mating threads. Consequently only the remaining 10% of input energy is turned into bolt stretch.