Pipe dimensioning

The length of the pipe is from the compressor to the farthest point.

– For a closed ring the diameter can be reduced by 29%.

– For pressed stainless steel pipe reduce the diameter by 6%

– For aluminum pipes reduce the diameter by 9%.

– Frequent loss of pressure 0.1-0.3 bar

– A maximum pressure loss of 0.1 bar is recommended.

A loss of pressure of 0.4 bar or higher is not profitable.

0.4 bar of pressure loss supposes an additional 3% of consumption.

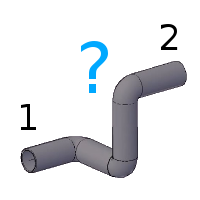

1) Main and secondary pipes. Distributions of small and medium extension: from 2.3 to 10 m/s.

2) Main pipes for long distances: from 5 to 6 m/s.

3) Machine feed pipes: up to 25 m/s

4) Pipes that join the different devices. Copper tubes and small distance: Up to 50 m/s.

5) Air intake hoses for pneumatic tools: from 15 to 20 m/s.

6) Long hoses used in works and shipyards: from 5 to 6 m/s.

2) Main pipes for long distances: from 5 to 6 m/s.

3) Machine feed pipes: up to 25 m/s

4) Pipes that join the different devices. Copper tubes and small distance: Up to 50 m/s.

5) Air intake hoses for pneumatic tools: from 15 to 20 m/s.

6) Long hoses used in works and shipyards: from 5 to 6 m/s.

Compressed Air Pipe Lines – Recommended Size Engineering Toolbox

TLV A steam specialist company