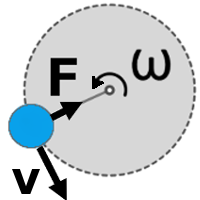

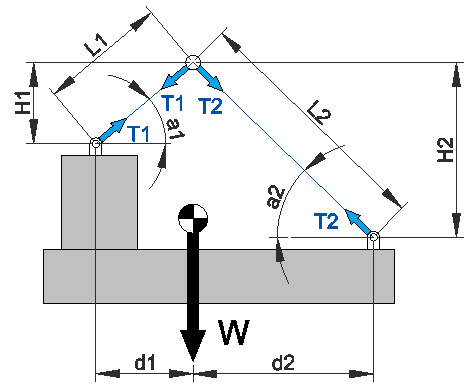

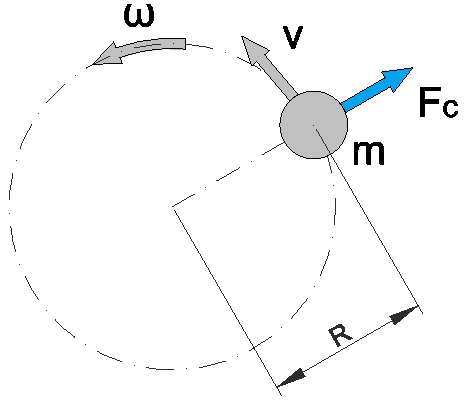

Centrifugal force

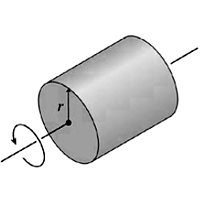

Centrifugal force is the inertia force that arises in each rotating object. It is only required in a rotating reference frame – or, in other words, when we look at the system from the point of view of the object in motion.

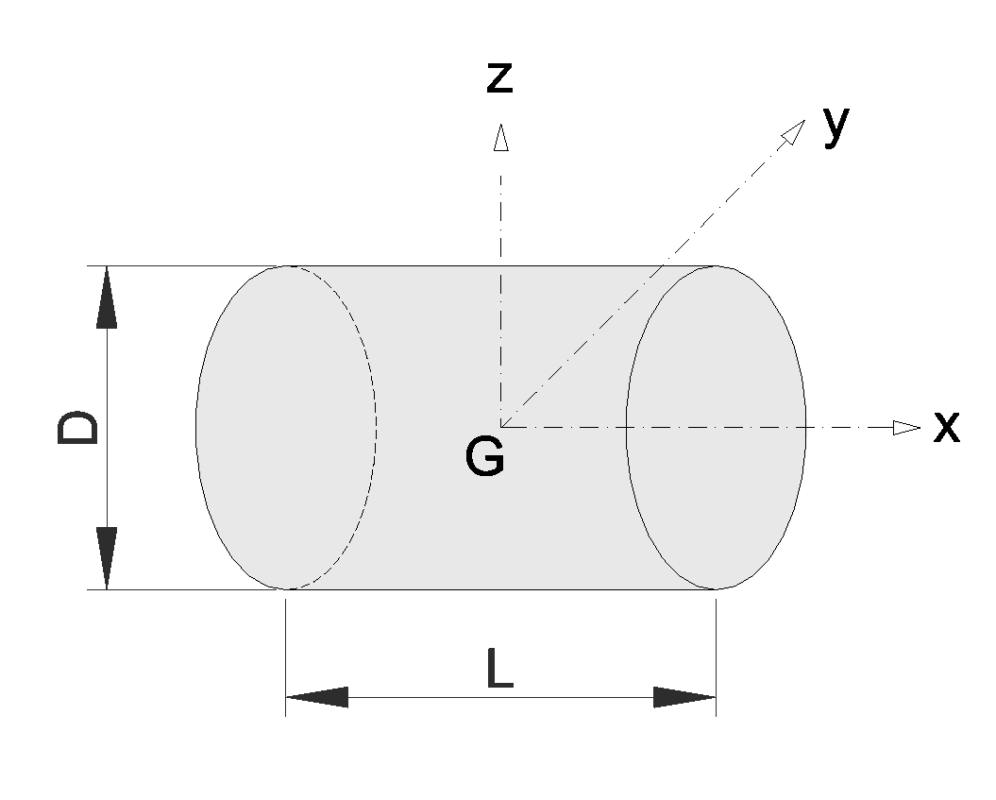

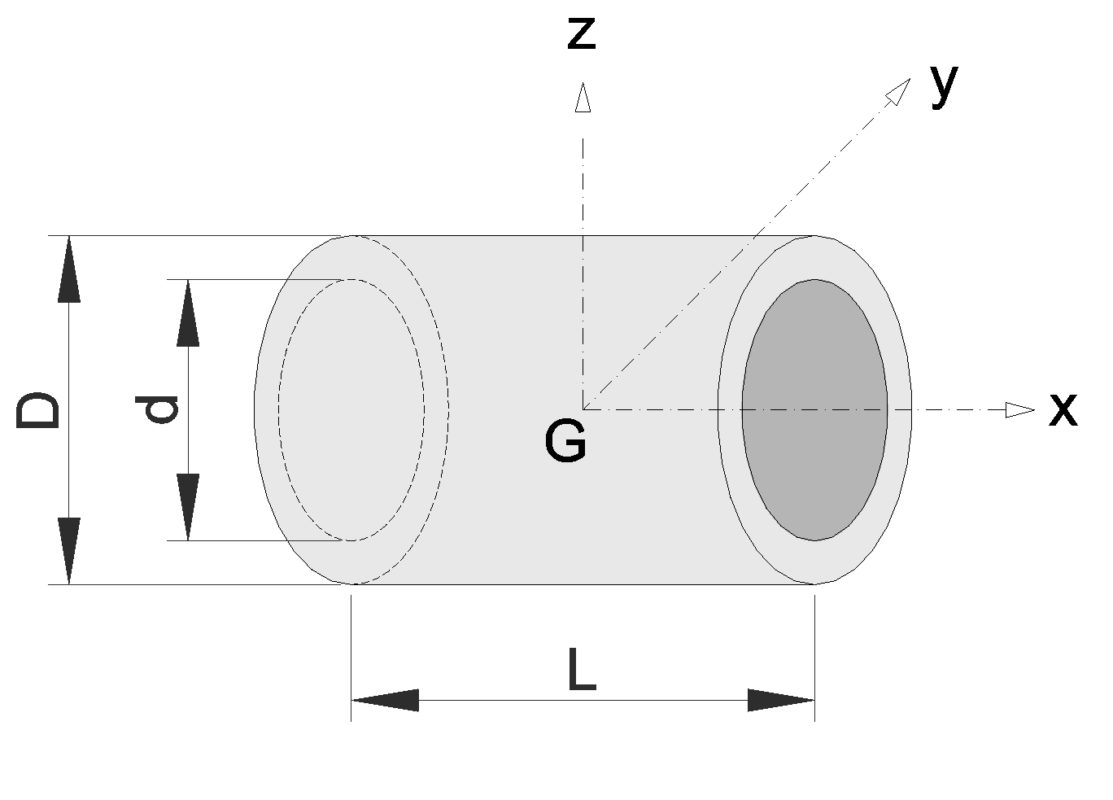

F: the force

m: the mass of the object

v: the velocity

R: the radius