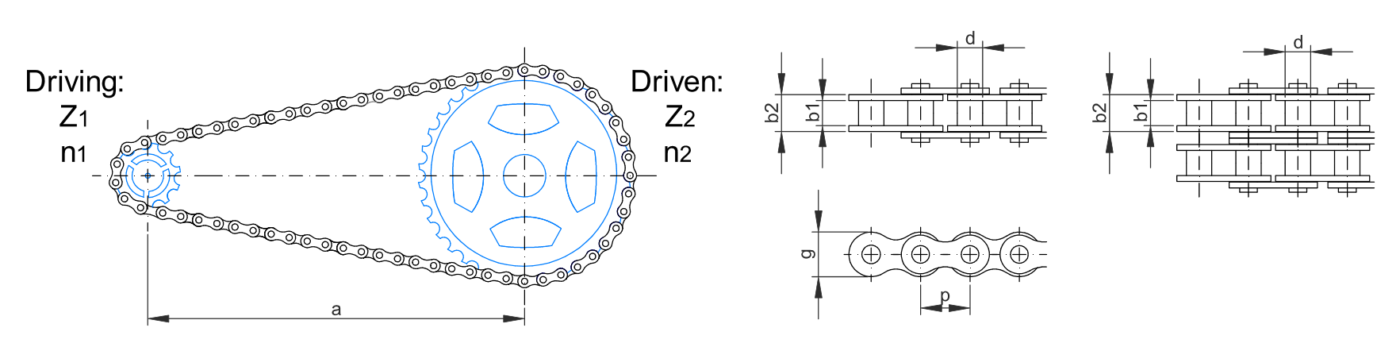

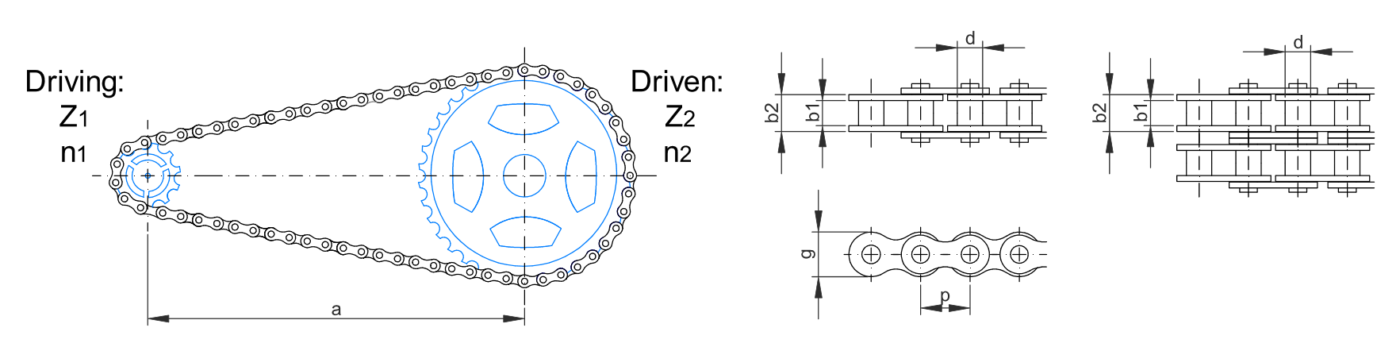

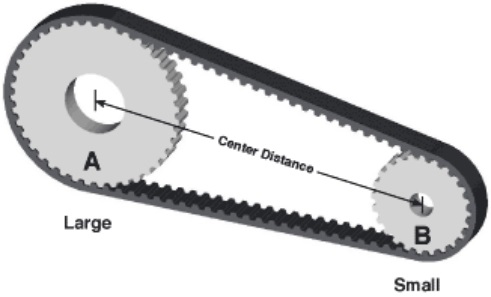

Roller Chain

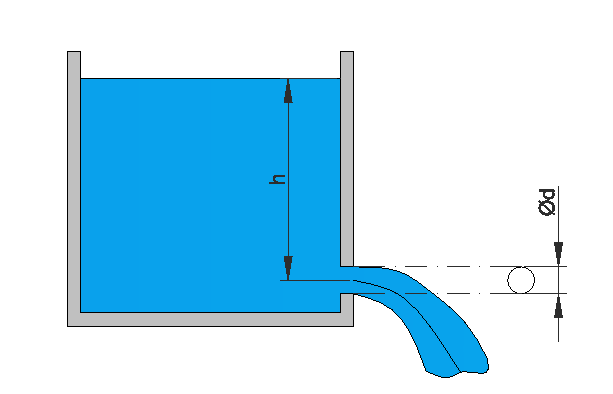

A tank with a circular hole of diameter d and at a depth h discharges water at a rate of Q.

The discharge rate is derived from Torricelli’s Principle and given by:

where

Q =discharge rate (m³/s)

h =depth of water (m)

A =area of opening (m²)

g =acceleration due to gravity (9.81 m/s²)

The torque required to tighten the bolt:

Where:

T: Torque (N.m)

K: Torque coefficient

F: Axial preload force (N)

d: Nominal bolt diameter (mm)

The torque coefficient:

Where:

l: Lead (mm)

α: Half angle of the screw thread (°)

d: Nominal bolt diameter (mm)

µ: Thread friction coefficient

µc: Collar friction coefficient

Common torque coefficient values for µ=µc=0.15:

| Bolt condition | K |

| Non plated black finish steel bolts | 0.3 |

| Mild steel bolts | 0.2 |

| Zinc plated steel bolts | 0.2 |

| Lubricated steel bolts | 0.18 |

| Cadmium plated steel bolts | 0.16 |

| With bowman anti-seize | 0.12 |

| With bowman-grip nuts | 0.09 |

It is estimated that roughly 90% of the input energy is lost in overcoming the mating friction under the head (collar) and between the thread or nut and its mating threads. Consequently only the remaining 10% of input energy is turned into bolt stretch.

This calculation is for a snap-fitting hook of rectangular cross section.There are two types which can be choosen for the calculation. Type 1 is a snap-fitting hook of a constant rectangular cross section and Type 2 is a snap-fitting hook of rectangular cross section with a constant decrease in thickness from h at the root to h/2 at the end of the hook. Young modulus and Yield strength of the material have to be choosen. The Deflection Force is the force required to bend the arm the value of the introduced deflection (y). Introducing the friction coefficient of the material and the angle of the arm according with the shape represented in picture, the mating force is calculated. This is the force required for introducing the snap-fitting hook. The calculus allows to ensure that the yield strength of the material won’t be exceeded as long as the safety coeficient is higher that 1. This calculation is an approximation because of we are only taking into account the shear due to bending.

The NPSH is related to the problem of cavitation. Cavitation means that the liquid pumped vaporizes within the pump which causes breakdown of suction column and head, loud noise, heavy vibration leading to erosion or pitting and possibly destruction of the impellers. The condition for operation without cavitation is:

NPSHa > NPSHr

Where:

NPSHa: NPSH available, of the plant.

NPSHr: NPSH required, of the pump. Lower value of NPSHr means greater the suction capability.

Usually is used a safety allowance of 0.5m.

P: Gas pressure. If the suction tank is open the gas pressure correspond to the atmospheric pressure (1 bar).

Vp: Vapour pressure of the fluid pumped at a given temperature.

ρ: Density of the fluid pumped.

g: gravitational constant 9.81 m/s2

S: Suction head. Vertical distance between suction tank and pump center line. (- ) for operation under suction lift conditions and (+) for operation under flooded suction conditions.

H: Head loss for the maximum flow in pipes, bends and valves on the suction side due to friction.

This calculator performs Pressure Drop Calculations for pipework. Additionaly, related parameters such as Reynolds, fluid velocity, average residence time, etcetera are presented. The Pressure Drop calculation takes into account other components as well. It requests the user for input about bends, elbows and other appendages/equipment components, which induce extra pressure loss. The program represents the total resistance in terms of equivalent pipe length values.