Category Archives: Info

Mechanical properties of materials

| TYPE | EN MATERIAL NUMBER | OTHER MATERIAL DESIGNATION | FORMING PROCESS | MODULUS OF ELASTICITY E (MPa) | MODULUS OF RIGIDITY G (MPa) | DENSITY ρ (kg/m3) | POISSON'S RATIO ν | YIELD STRENGTH Re; Rp0,2 (MPa) | TENSILE STRENGTH Rm (MPa) | COMMENTS |

|---|---|---|---|---|---|---|---|---|---|---|

| CARBON STEEL | 1.0045 | |||||||||

| STAINLESS STEEL | 1.4310 | 212000 | 8030 | 0.3 | 205 | 515 | ||||

| STAINLESS STEEL | 1.4305 | 193000 | 8000 | 0.25 | 240 | 620 | ||||

| STAINLESS STEEL | 1.4301 | 193000 | 7900 | 0.29 | 210 | 505 | ||||

| STAINLESS STEEL | 1.4307 | 193000 | 7900 | 0.29 | 210 | 505 | ||||

| STAINLESS STEEL | 1.4401 | 193000 | 8000 | 0.3 | 240 | 550 | ||||

| STAINLESS STEEL | 1.4435 | 193000 | 8000 | 0.3 | 240 | 550 | ||||

| BRONZE | 103421 | 8850 | 0.34 | 110 | 250 | Type CUSN12 - B12 | ||||

| POM C (DELRIN) | 3000 | 1390 | 63 | 115 | ||||||

| POLICARBONATE | 2200 | 1200 | 0.37 | 65-35 | 65 | |||||

| PMMA (METHACRYLATE) | 3300 | 1180 | 0.45 | 72 | ||||||

| TITANIUM | 115000 | 4730 | 830 | 900 | ||||||

| STRUCTURAL STEEL A36 | 1.0117 | 200000 | 77200 | 7860 | 250 | 400 | ||||

| ALUMINUM 1100-H14 | 70000 | 26000 | 2710 | 0.33 | 95 | 110 | 99% Al | |||

| ALUMINUM 2014-T6 | 75000 | 27000 | 2800 | 400 | 455 | |||||

| ALUMINUM 2024-T4 | 73000 | 2800 | 325 | 470 | ||||||

| ALUMINUM 5456-H116 | 72000 | 2630 | 230 | 315 | ||||||

| ALUMINUM 6061-T6 | 70000 | 26000 | 2710 | 0.33 | 240 | 260 | ||||

| ALUMINUM 7075-T6 | 72000 | 28000 | 2800 | 500 | 570 | |||||

| GLASS | 65000 | 4100 | 2190 | 98% silica |

Safety factor

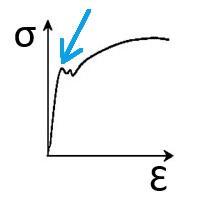

Nductile ≥ max(N1, N2, N3) ; based on yield strength

Nbrittle ≥ max(N1, N2, N3) ; based on ultimate strength

N = N1 . N2

N1 = f(A, B, C), from the first table

N2 = f(D, E) , from the second table

Parameters:

A Quality of materials, workmanship, maintenance and inspection

B Control over applied loads

C Accuracy of stress analysis, experimental data, or experience with similar parts

D Danger to people

E Economic impact

The transition from engineering model to reality is usually facilitated by including a factor of safety in the design to accommodate uncertainly in material properties and the design process, the consequences of failure, risk to people and degree of characterization of and control over the service environment.

Safety factor is a simple ratio that is intended to be greater than 1.

Safety factors for ductile materials are based on yield strength. Safety factors for brittle materials are based on ultimate strength and are twice the recommended values for ductile materials. Safety factors for primarily cyclic loading are based on endurance limit. Impact loads require a safety factor of at least 2 multiplied by an impact factor from 1.1 to 2.

The factor safety is often specified in a design code or standard.

Factor safety is affected by:

- Material strength basis: Brittle materials use ultimate strength and ductile use yield strength.

- Manner of loading: Static applied slowly, repeated; fatigue failure may occur; impact; high initial stresses develop.

- Possible misuse: Designer must consider any reasonable foreseeable use of misuse of product.

- Complexity of stress analysis.

- Environment: Temperature, weather, radiation, quimical…

- Hazard of failure; What happens if the parts fail?

- Cost.

- Market segment: Different safety factor for different markets (aerospace, health…)

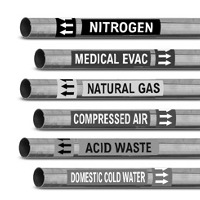

Colours for the identification of pipelines

DIN 2403 defines the identification of pipes according to the fluid conveyed.

The pipelines shall be clearly idetified by labels specifying the nature of the fluid conveyed with labels or adhesive labels. The size of the labels shall be selected fron DIN 825 Part 1.

Standards and other documents referred to:

DIN 825 Part 1 Dimensions of nameplates; square and rectangular nameplates

DIN 1304 Symbols for formulae

DIN 6164 Part1 DIN colour chart

DIN 25400 Warning symbol for ionizing radiation

RAL 840 HR Colour register

ANSI/ASME A13.1 Pipe identification standard used in the United States

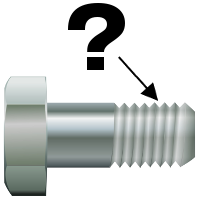

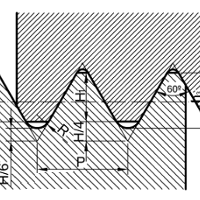

Thread identification guide

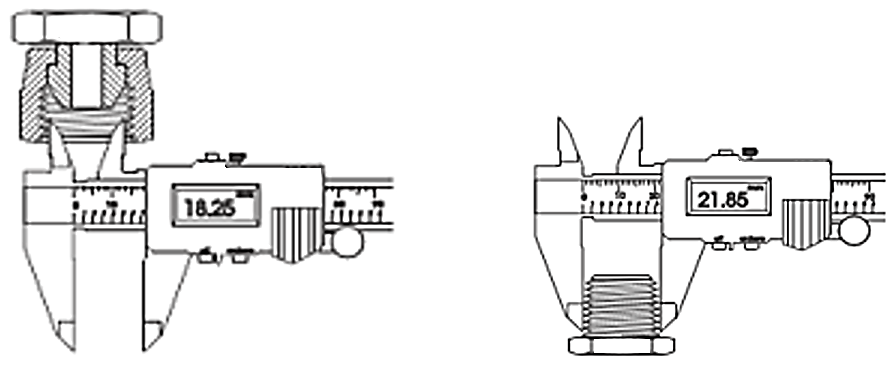

STEP 1

Determine if the thread is tapered or parallel/straight.

Measure the thread with a caliper at the beginning and the end. If the diameters increase for a male end or decrease for a female end, the thread is tapered. If it is the same value the thread is straight/parallel.

STEP 2

Determine the thread size and type. Imperial sizes are normally common fractions ¼”=0.25”.

Measure the outside diameter OD for male and inside ID for female threads.

If the thread is tapered measure the diameter of 4th or 5th full thread.

The diameter measurement obtained in this step may not be exactly the same as the listed nominal size for the given thread. This variation is due to manufacturing tolerances.

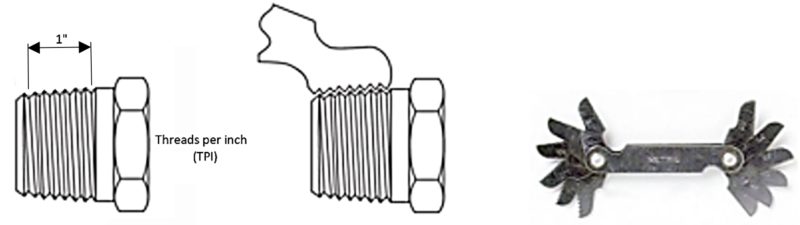

STEP 3

Determine the pitch for metric or the amount of threads per inch (T.P.I) for imperial sizes.

In both cases Thread pitch gauges can be used.

| TPI | 28 | 27 | 24 | 20 | 19 | 18 | 16 | 14 | 12 | 11.5 | 11 | 8 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread pitch (mm) | 0.91 | 0.94 | 1.06 | 1.27 | 1.34 | 1.4 | 1.59 | 1.81 | 2.12 | 2.21 | 2.31 | 3.18 |

Check for any markings on fitting or equipment which may be a clue to thread type. Country of origin may provide a clue.

Europe (DIN,BSP), America (NPT, JIC, UNO, ORFS), UK/Australia (BSP), Japan (JIS).

Thread types

| Symbol | Angle | Parallel/tapered | Standard | Description | Application |

|---|---|---|---|---|---|

| A/B | 60° | Parallel | DIN 4503, ISO 1222 | Tripod connection thread | Connections to photografic equipment. |

| ACME-C | 29° | ANSI B1.5 (1977) | Acme thread centralizing | ||

| ACME-G | 29° | ANSI B1.5 (1977) | Acme thread general purpose | ||

| AMO | 55° | ANSI B1.11 (1958) | American standard microscope objective thread | ||

| ANPT | 60° | MIL-P-7105 | Aeronautical national form taper pipe thread | ||

| API | 60° | American national taper form thread for petroleum installations | |||

| BA | 47°30' | BS93 (1951) | British association thread | ||

| BSC | 60° | BS811 (1950) | British norm thread for bicycles | ||

| BSF | 55° | Parallel | BS84 (1956) | Whithworth fine thread | |

| BSW | 55° | Parallel | BS84 (1956) | Whithworth coarse thread | |

| E | - | DIN 40400, DIN 49612, DIN 49610, DIN 49625 | Edison form thread | Electrical thread. | |

| EG M | 60° | Parallel | DIN 8140-2 | Metric ISO thread for helical coil wire screw thread inserts | For wire thread inserts. |

| EG-UNC | 60° | Parallel | MS 33537 | Unified coarse thread series for helical coil wire screw thread inserts | |

| EG-UNF | 60° | Parallel | ASME B18.29.1 | Unified fine thread for helical coil wire screw thread inserts | |

| FG | 60° | Parallel | DIN 79012 | Bicycle thread | For cycles and motor-scooters. |

| G | 55° | Parallel | DIN ISO 228, DIN 6630 | Pipe parallel ISO thread | For pressure tight joints are not made on the thread. External and internal pipe thread. Packaging; external thread for barrels. |

| G | 55° | Parallel | BS2779 (1973) | Pipe whitworth thread (BSP)parallel | |

| Gf | Tapered | DIN 4930 | Round tapered thread | Tubes and tunneling | |

| Gg | 60° | Tapered (1:16) | DIN 4941 | Tapered thread | For drill pipes in water and rock drilling, mining. |

| Gg | 30°-30° | Tapered (1:4) | DIN 20314 | Tapered thread | For drill pipes in water and rock drilling, mining. |

| GL | 30°-60° | Parallel | DIN 168-1 | Cylindrical round thread | For glass containers. |

| Glasg | 30°-50° | Parallel | DIN 40450 | Glasg thread for glass | Electric industry: glass fittings, protection glasses. |

| HA-HB | DIN 58810 | Bone screw thread | For surgical implants, external and internal thread. | ||

| KT | 20° | Parallel | DIN 6063 | Trapezoidal thread | Preferably for packages made of plastics. |

| LN | 60° | Parallel | LN 9163, EN 2158 | ISO Metric thread for aviation | Aviation and aerospace. |

| M | 60° | Parallel | DIN 13, DIN 14, ISO 68, DIN 6630, LN 9163, DIN 2510 | Metric coarse ISO thread | General engineering, watches, fine work, packaging; external thread for barrels, aviation, aerospace and bolted connections with reduced shank. |

| M | 60° | Tapered (1:16) | DIN 158 | Taper metric ISO thread | Plugs and grease nipples. |

| MF | 60° | Parallel | DIN 13, DIN EN 60423 | Metric fine ISO thread | |

| MFS | 60° | Parallel | DIN 8141-1 | ISO Metric thread for tight fit | |

| MJ | 60° | Parallel | DIN ISO 5855 | Metric ISO thread for aeronautics | Aviation and aerospace. |

| N | 60° | ANSI B1.1 (1960) | American national 8-12-16 TPI pitch series (8N, 12N, 16N) | ||

| N-BUTT | 45°+5° | ANSI B1.9 (1973) | American BUTTRESS thread | ||

| NC | 60° | ANSI B1.1 (1960) | American national coarse thread series | ||

| NEF | 60° | ANSI B1.1 (1960) | American national extra fine thread series | ||

| NF | 60° | ANSI B1.1 (1960) | American national fine thread series | ||

| NGO | 60° | ANSI/ASME-B1.20.1 (1983) | National gas outlet thread (specify RH or LH) | ||

| NGS | 60° | ANSI/ASME-B1.20.1 (1983) | National gas straight thread | ||

| NGT | 60° | ANSI B57.1 (1977) | National gas taper thread (see also SGT) | ||

| NH | 60° | ANSI B2.4 H28 (1966) | American national firehouse and hose coupling thread | ||

| NPS | 60° | American standard straight pipe thread NSPC & NPSM | |||

| NPSC | 60° | ANSI/ASME-B1.20.1 (1983) | American standard straight pipe thread in pipe couplings (marked NPS) | ||

| NPSF | 60° | ANSI B1.20.3 (1976) | Dryseal American standard internal straight pipe thread (fuel) | ||

| NPSH | 60° | ANSI/ASME-B1.20.1 (1983) | American standard straight pipe thread for hose couplings | ||

| NPSI | 60° | ANSI B1.20.3 (1976) | American standard intermediate internal straight pipe thread | ||

| NPSL | 60° | ANSI/ASME-B1.20.1 (1983) | American standard straight pipe thread for loose-fitting mechanical joints | ||

| NPSM | 60° | ANSI/ASME-B1.20.1 (1983) | American standard straight pipe thread for free-fitting mechanical joints | ||

| NPT | 60° | Tapered (1:16) | ANSI/ASME-B1.20.1 (1983) | American standard tapered pipe thread | For threads with dryseal material. |

| NPTF | 60° | Tapered (1:16) | ANSI B1.20.3 (1976) | American standard tapered pipe thread (fuel) | For threads without dryseal material. |

| NPTR | 60° | ANSI/ASME-B1.20.1 (1983) | American standard taper pipe thread for railing joints (tap market NPT) | ||

| NS | 60° | ANSI B1.1 (1960) | American national thread special pitches | ||

| Pg | 80° | Parallel | DIN 40430 | Steel electrical conduit thread | For electric installations. |

| PTF | 60° | ANSI B1.20.1 (1976) | Dryseal SAE short taper pipe thread | ||

| R | 55° | Parallel | DIN 259 | Pipe parallel whitworth thread | For pressure tight joints are not made on the thread. Piping, do not use in new designs. |

| R | 55° | Tapered (1:16) | BS21 (1985), DIN EN 10226-1, ISO 7-1, DIN 2999, DIN 3858 | External dryseal pipe taper thread (BSPT) | Tapered Whitworth pipe thread where pressure-tight joints are made on the threads. |

| Rc | 55° | Tapered (1:16) | BS21 (1985), DIN EN 10226-1, ISO 7-1 | Internal dryseal pipe taper thread (BSPT) | Tapered Whitworth pipe thread where pressure-tight joints are made on the threads. |

| Rd | 30° | Parallel | DIN 405, DIN 20400, DIN 15403, DIN 7273 | Rounded thread | General, for mining industry, for lifting hooks, for steel sheet items and related joints. |

| RMS | 55° | Parallel | DIN 58888 | RMS-thread | Objective for microscope. |

| Rp | 55° | Parallel | DIN 2999, DIN 3858 | Internal dryseal parallel thread | Internal thread for pipes and fittings. |

| Rp | 55° | Parallel | BS21 (1973), DIN EN 10226-1, ISO 7-1 | Pipe parallel thread (BSPP) | Cylindrical Whitworth pipe thread where pressure-tight joints are made on the threads. |

| S | 30°+3° | Parallel | DIN 513, DIN 20401 | Saw form thread | General. Mining industry. |

| S | 45° | Parallel | DIN 2781 | Saw form thread | For machine tools, hydraulic presses. |

| S | 105° | Tapered (7°30') | DIN 71412 | Self forming taper external thread | Taper lubricating nipple. Similar to DIN 158 but 105° thread angle. |

| SB | Manufacturers stovebolt standards thread | ||||

| SGT | 60° | ANSI B57.1 (1977) | Special gas taper thread | ||

| SPL-PTF | 60° | ANSI B1.20.3 (1976) | Dryseal special taper pipe thread | ||

| ST | 60° | Parallel | DIN 7970, DIN EN ISO 1478 | Sheet metal screw thread | For tapping screws. |

| STI | 60° | Special thread for helical coil wire screw thread inserts | |||

| STUB-ACME | 29° | ANSI B1.8 (1977) | Stub Acme thread | ||

| Tr | 30° | Parallel | DIN 103, DIN 380, DIN 263, DIN 6341, DIN 30295 | Trapezoidal thread | General, for rail vehicles, for collet chucks. |

| UN | 60° | ANSI B1.1 (1982) | Unified 8-12-16 TPI pitch series | ||

| UN-8 | 60° | ASME B1.1 | Unified thread for special diameters and pitches | ||

| UNC | 60° | ANSI B1.1 (1982) | Unified coarse thread series | ||

| UNEF | 60° | ANSI B1.1 (1982) | Unified extra fine thread series | ||

| UNF | 60° | ANSI B1.1 (1982) | Unified fine thread series | ||

| UNJ | 60° | BS 4048 (1978) | Unified constant pitch with a 0,15011P to 0,18042P controlled root radius | ||

| UNJC | 60° | BS 4048 (1978), ASME B1.15 | Unified coarse thread with a 0,15011P to 0,18042P controlled root radius | ||

| UNJEF | 60° | BS 4048 (1978) | Unified extra fine thread with a 0,15011P to 0,18042P controlled root radius | ||

| UNJF | 60° | BS 4048 (1978), ASME B1.15 | Unified fine thread with a 0,15011P to 0,18042P controlled root radius | ||

| UNM | 60° | ASA B1.10 (1958) | Unified miniature thread series | ||

| UNS | 60° | ANSI B1.1 (1982) | Unified thread special pitches | ||

| V | 60° | 60° "V" thread with truncated crest and root(flatted to the user's specifications) | |||

| Vg | 60° | Parallel | DIN 7756 | Valves thread | Valves for tires. |

| W | 55° | Parallel | DIN 477 | Parallel whitworth thread | Cylindrical thread for side connections. |

| W keg | 55° | Tapered (3:25) | DIN 477, DIN EN 144-1, DIN EN 629-1, DIN EN ISO 11116-1 | Tapered thread for screw sockets | Gas cylinders, thread for side nozzles. |

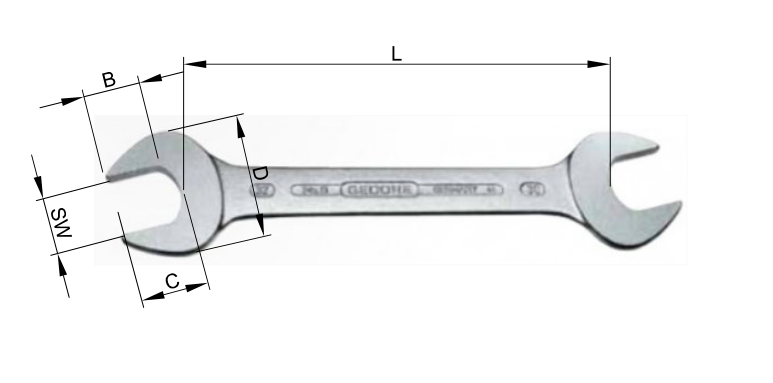

Tool dimensions

ISO 1085

DIN 3110

| Screw | SW | D | B | C | L |

|---|---|---|---|---|---|

| M3 | 6 | 16 | 3.8 | 5.4 | 100 |

| M4 | 7 | 18 | 4.2 | 6.3 | 100 |

| M5 | 8 | 19 | 4.8 | 7.2 | 110 |

| M6 | 10 | 23 | 5 | 9 | 110 |

| M8 | 13 | 32 | 7.8 | 11.7 | 110 |

| M10 | 17 | 40 | 10.2 | 15.3 | 140 |

| M12 | 19 | 44 | 11.4 | 17.1 | 160 |

| M14 | 22 | 49 | 13.2 | 19.8 | 170 |

| M16 | 24 | 54 | 14.4 | 21.6 | 180 |

| M18 | 27 | 60 | 16.2 | 24.3 | 190 |

| M20 | 30 | 66 | 18 | 27 | 200 |

| M22 | 32 | 70 | 19.2 | 28.8 | 210 |

| M24 | 36 | 78 | 21.6 | 32.4 | 220 |

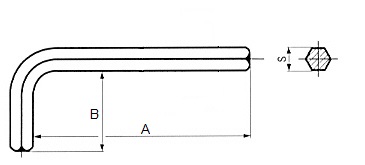

ISO 2936

DIN 911

| Screw | s | A | B |

|---|---|---|---|

| M3 | 2.5 | 56 | 18 |

| M4 | 3 | 63 | 20 |

| M5 | 4 | 70 | 25 |

| M6 | 5 | 80 | 28 |

| M8 | 6 | 90 | 32 |

| M10 | 8 | 100 | 36 |

| M12 | 10 | 112 | 40 |

| M14 | 12 | 125 | 45 |

| M16 | 14 | 140 | 56 |

| M18 | 14 | 140 | 56 |

| M20 | 17 | 160 | 63 |

| M22 | 17 | 160 | 63 |

| M24 | 19 | 180 | 70 |

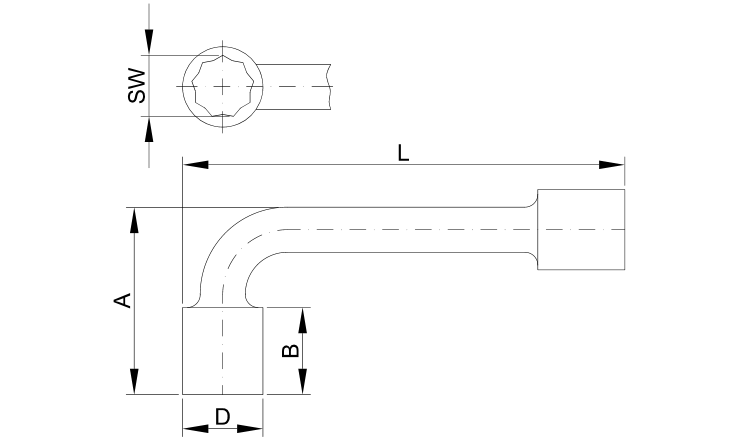

| Screw | SW | D | B | A | L |

|---|---|---|---|---|---|

| M3 | 6 | 9 | 10 | 23 | 104 |

| M4 | 7 | 11 | 11 | 23 | 116 |

| M5 | 8 | 13 | 13 | 27 | 125 |

| M6 | 10 | 15 | 15 | 35 | 160 |

| M8 | 13 | 19 | 19 | 45 | 188 |

| M10 | 17 | 25 | 24 | 52 | 255 |

| M12 | 19 | 27 | 29 | 60 | 285 |

| M14 | 22 | 31 | 31 | 70 | 314 |

| M16 | 24 | 34 | 34 | 75 | 342 |

| M18 | 27 | 38 | 40 | 80 | 375 |

| M20 | 30 | 42 | 43 | 85 | 400 |

| M22 | 32 | 45 | 45 | 90 | 420 |

| M24 | 36 | 50 | 52 | 95 | 440 |

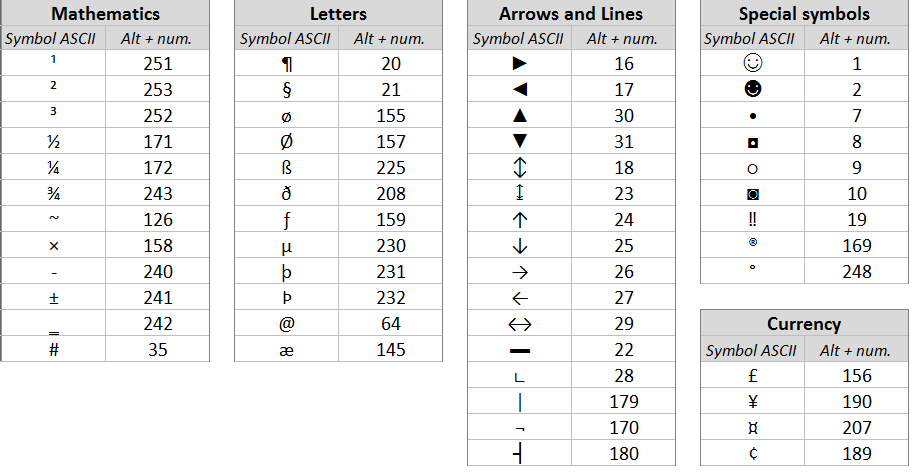

ASCII characters and symbols

| Alt+num | Ascii symbol | Description |

|---|---|---|

| 0 | NULL | Null character |

| 1 | SOH | Start of Header |

| 2 | STX | Start of Text |

| 3 | ETX | End of Text |

| 4 | EOT | End of Transmission |

| 5 | ENQ | Enquiry |

| 6 | ACK | Acknowledgement |

| 7 | BEL | Bell |

| 8 | BS | Backspace |

| 9 | HT | Horizontal Tab |

| 10 | LF | Line feed |

| 11 | VT | Vertical Tab |

| 12 | FF | Form feed |

| 13 | CR | Carriage return |

| 14 | SO | Shift Out |

| 15 | SI | Shift In |

| 16 | DLE | Data link escape |

| 17 | DC1 | Device control 1 |

| 18 | DC2 | Device control 2 |

| 19 | DC3 | Device control 3 |

| 20 | DC4 | Device control 4 |

| 21 | NAK | Negative acknowledgement |

| 22 | SYN | Synchronous idle |

| 23 | ETB | End of transmission block |

| 24 | CAN | Cancel |

| 25 | EM | End of medium |

| 26 | SUB | Substitute |

| 27 | ESC | Escape |

| 28 | FS | File separator |

| 29 | GS | Group separator |

| 30 | RS | Record separator |

| 31 | US | Unit separator |

| 32 | Space | |

| 33 | ! | Exclamation mark |

| 34 | " | Quotation mark ; quotes |

| 130 | é | letter "e" with acute accent or "e-acute" |

| 131 | â | letter "a" with circumflex accent or "a-circumflex" |

| 132 | ä | letter "a" with umlaut or diaeresis ; "a-umlaut" |

| 133 | à | letter "a" with grave accent |

| 134 | å | letter "a" with a ring |

| 135 | ç | Minuscule c-cedilla |

| 136 | ê | letter "e" with circumflex accent or "e-circumflex" |

| 137 | ë | letter "e" with umlaut or diaeresis ; "e-umlaut" |

| 138 | è | letter "e" with grave accent |

| 139 | ï | letter "i" with umlaut or diaeresis ; "i-umlaut" |

| 140 | î | letter "i" with circumflex accent or "i-circumflex" |

| 141 | ì | letter "i" with grave accent |

| 142 | Ä | letter "A" with umlaut or diaeresis ; "A-umlaut" |

| 143 | Å | Capital letter "A" with a ring |

| 144 | É | Capital letter "E" with acute accent or "E-acute" |

| 145 | æ | Latin diphthong "ae" in lowercase |

| 146 | Æ | Latin diphthong "AE" in uppercase |

| 147 | ô | letter "o" with circumflex accent or "o-circumflex" |

| 148 | ö | letter "o" with umlaut or diaeresis ; "o-umlaut" |

| 149 | ò | letter "o" with grave accent |

| 150 | û | letter "u" with circumflex accent or "u-circumflex" |

| 151 | ù | letter "u" with grave accent |

| 152 | ÿ | Lowercase letter "y" with diaeresis |

| 153 | Ö | letter "O" with umlaut or diaeresis ; "O-umlaut" |

| 154 | Ü | letter "U" with umlaut or diaeresis ; "U-umlaut" |

| 155 | ø | slashed zero or empty set |

| 156 | £ | Pound sign ; symbol for the pound sterling |

| 157 | Ø | slashed zero or empty set |

| 158 | × | multiplication sign |

| 159 | ƒ | function sign ; f with hook sign ; florin sign |

| 160 | á | letter "a" with acute accent or "a-acute" |

| 161 | í | letter "i" with acute accent or "i-acute" |

| 162 | ó | letter "o" with acute accent or "o-acute" |

| 163 | ú | letter "u" with acute accent or "u-acute" |

| 164 | ñ | letter "n" with tilde ; enye |

| 165 | Ñ | letter "N" with tilde ; enye |

| 166 | ª | feminine ordinal indicator |

| 167 | º | masculine ordinal indicator |

| 168 | ¿ | Inverted question marks |

| 169 | ® | Registered trademark symbol |

| 170 | ¬ | Logical negation symbol |

| 171 | ½ | One half |

| 172 | ¼ | Quarter or one fourth |

| 173 | ¡ | Inverted exclamation marks |

| 174 | « | Angle quotes or guillemets |

| 175 | » | Guillemets or angle quotes |

| 176 | ░ | Square grey dash 25% |

| 177 | ▒ | Square grey dash 50% |

| 178 | ▓ | Square grey dash 75% |

| 179 | │ | Box drawing character |

| 180 | ┤ | Box drawing character |

| 181 | Á | Capital letter "A" with acute accent or "A-acute" |

| 182 | Â | letter "A" with circumflex accent or "A-circumflex" |

| 183 | À | letter "A" with grave accent |

| 184 | © | Copyright symbol |

| 185 | ╣ | Box drawing character |

| 186 | ║ | Box drawing character |

| 187 | ╗ | Box drawing character |

| 188 | ╝ | Box drawing character |

| 189 | ¢ | Cent symbol |

| 190 | ¥ | YEN and YUAN sign |

| 191 | ┐ | Box drawing character |

| 192 | \ | Box drawing character |

| 193 | ┴ | Box drawing character |

| 194 | ┬ | Box drawing character |

| 195 | ├ | Box drawing character |

| 196 | ─ | Box drawing character |

| 197 | ┼ | Box drawing character |

| 198 | ã | Lowercase letter "a" with tilde or "a-tilde" |

| 199 | Ã | Capital letter "A" with tilde or "A-tilde" |

| 200 | ╚ | Box drawing character |

| 201 | ╔ | Box drawing character |

| 202 | ╩ | Box drawing character |

| 203 | ╦ | Box drawing character |

| 204 | ╠ | Box drawing character |

| 205 | ═ | Box drawing character |

| 206 | ╬ | Box drawing character |

| 207 | ¤ | generic currency sign |

| 208 | ð | Lowercase letter "eth" |

| 209 | Ð | Capital letter "Eth" |

| 210 | Ê | letter "E" with circumflex accent or "E-circumflex" |

| 211 | Ë | letter "E" with umlaut or diaeresis ; "E-umlaut" |

| 212 | È | letter "E" with grave accent |

| 213 | ı | lowercase dot less i |

| 214 | Í | Capital letter "I" with acute accent or "I-acute" |

| 215 | Î | letter "I" with circumflex accent or "I-circumflex" |

| 216 | Ï | letter "I" with umlaut or diaeresis ; "I-umlaut" |

| 217 | ┘ | Box drawing character |

| 218 | ┌ | Box drawing character |

| 219 | █ | Block |

| 220 | ▄ | Bottom half block |

| 221 | ¦ | vertical broken bar |

| 222 | Ì | letter "I" with grave accent |

| 223 | ▀ | Top half block |

| 224 | Ó | Capital letter "O" with acute accent or "O-acute" |

| 225 | ß | letter "Eszett" ; "scharfes S" or "sharp S" |

| 226 | Ô | letter "O" with circumflex accent or "O-circumflex" |

| 227 | Ò | letter "O" with grave accent |

| 228 | õ | letter "o" with tilde or "o-tilde" |

| 229 | Õ | letter "O" with tilde or "O-tilde" |

| 230 | µ | Lowercase letter "Mu" ; micro sign or micron |

| 231 | þ | Lowercase letter "Thorn" |

| 232 | Þ | Capital letter "thorn" |

| 233 | Ú | Capital letter "U" with acute accent or "U-acute" |

| 234 | Û | letter "U" with circumflex accent or "U-circumflex" |

| 235 | Ù | letter "U" with grave accent |

| 236 | ý | Lowercase letter "y" with acute accent |

| 237 | Ý | Capital letter "Y" with acute accent |

| 238 | ¯ | macron symbol |

| 239 | ´ | Acute accent |

| 240 | | Hyphen |

| 241 | ± | Plus-minus sign |

| 242 | ‗ | underline or underscore |

| 243 | ¾ | three quarters |

| 244 | ¶ | paragraph sign or pilcrow |

| 245 | § | Section sign |

| 246 | ÷ | The division sign ; Obelus |

| 247 | ¸ | cedilla |

| 248 | ° | degree symbol |

| 249 | ¨ | Diaeresis |

| 250 | · | Interpunct or space dot |

| 251 | ¹ | superscript one |

| 252 | ³ | cube or superscript three |

| 253 | ² | Square or superscript two |

| 254 | ■ | black square |

| 255 | nbsp | non-breaking space or no-break space |