O-Rings

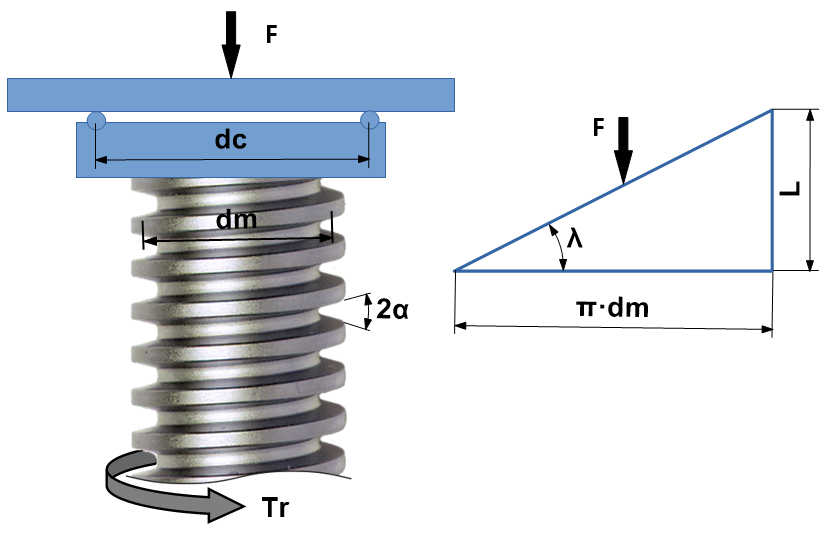

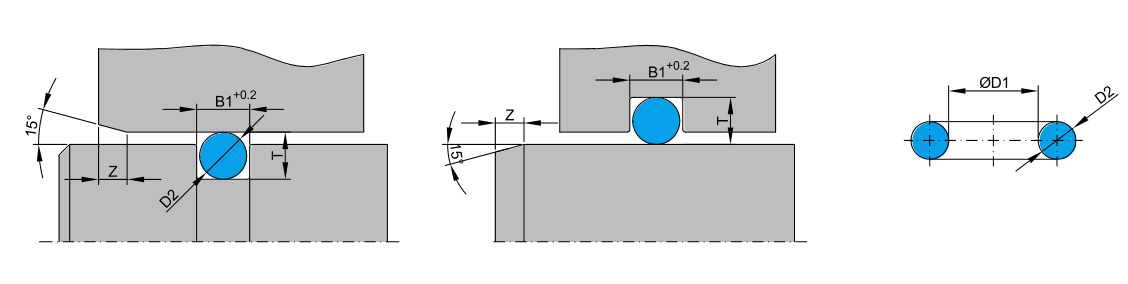

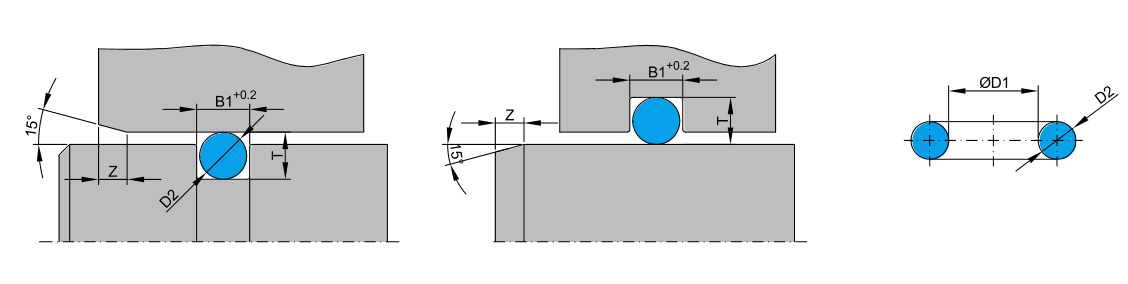

| D2 | T | B1 | Z |

|---|---|---|---|

| 1.5 | 1,1±0,06 | 2.2 | 2.1 |

| 1.6 | 1,2±0,06 | 2.3 | 2.1 |

| 1.78 | 1,4±0,07 | 2.4 | 2.1 |

| 1.8 | 1,4±0,07 | 2.5 | 2.1 |

| 2 | 1,5±0,08 | 2.8 | 2.6 |

| 2.4 | 1,8±0,1 | 3.4 | 3 |

| 2.5 | 1,9±0,1 | 3.4 | 3 |

| 2.62 | 2±0,1 | 3.6 | 3.1 |

| 2.65 | 2±0,11 | 3.7 | 3.2 |

| 3 | 2,3±0,12 | 4.1 | 3.5 |

| 3.5 | 2,7±0,14 | 4.7 | 3.9 |

| 3.53 | 2,7±0,14 | 4.8 | 4 |

| 3.55 | 2,7±0,14 | 4.8 | 4 |

| 4 | 3,1±0,16 | 5.4 | 4.5 |

| 4.5 | 3,5±0,18 | 6 | 4.9 |

| 5 | 3,9±0,2 | 6.6 | 5.4 |

| 5.3 | 4,1±0,21 | 7 | 5.8 |

| 5.33 | 4,1±0,21 | 7.1 | 6 |

| 5.5 | 4,3±0,22 | 7.2 | 6.1 |

| 5.7 | 4,4±0,23 | 7.6 | 6.3 |

| 6 | 4,7±0,24 | 7.8 | 6.4 |

| 6.5 | 5,1±0,26 | 8.4 | 6.8 |

| 6.99 | 5,5±0,28 | 9 | 7.2 |

| 7 | 5,5±0,28 | 9 | 7.3 |

| 7.5 | 5,9±0,3 | 9.7 | 7.7 |

| 8 | 6,3±0,32 | 10.3 | 8.2 |

| 8.4 | 6,4±0,32 | 10.4 | 8.3 |

| 8.5 | 6,7±0,34 | 10.9 | 8.7 |

| 9 | 7,1±0,36 | 11.6 | 9.2 |

| 9.5 | 7,5±0,38 | 12.2 | 9.6 |

| 10 | 7,9±0,4 | 12.8 | 10.1 |

| 10.5 | 8,2±0,42 | 13.6 | 11 |

| 11 | 8,6±0,43 | 14.1 | 11.3 |

| 11.5 | 9±0,46 | 14.7 | 11.8 |

| 12 | 9,4±0,48 | 15.5 | 12.4 |

| 12.5 | 9,8±0,5 | 16.1 | 12.8 |

| 13 | 10,2±0,52 | 16.7 | 13.3 |

| 13.5 | 10,6±0,54 | 17.3 | 13.8 |

| 14 | 11±0,56 | 17.9 | 14.2 |

| 14.5 | 11,4±0,58 | 18.5 | 14.7 |

| 15 | 11,8±0,6 | 19.1 | 15.1 |

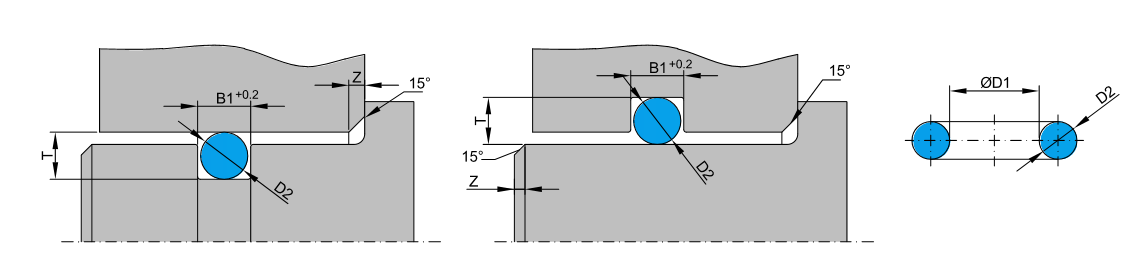

| D2 | H | B4 |

|---|---|---|

| 1.5 | 1,1±0,03 | 2.2 |

| 1.6 | 1,2±0,03 | 2.2 |

| 1.78 | 1,4±0,04 | 2.4 |

| 1.8 | 1,4±0,04 | 2.4 |

| 2 | 1,5±0,04 | 2.8 |

| 2.4 | 1,8±0,05 | 3.3 |

| 2.5 | 1,9±0,05 | 3.4 |

| 2.62 | 2±0,05 | 3.5 |

| 2.65 | 2±0,05 | 3.6 |

| 3 | 2,3±0,06 | 4 |

| 3.5 | 2,7±0,07 | 4.6 |

| 3.53 | 2,7±0,07 | 4.6 |

| 3.55 | 2,7±0,07 | 4.6 |

| 4 | 3,1±0,08 | 5.2 |

| 4.5 | 3,5±0,09 | 5.8 |

| 5 | 3,9±0,1 | 6.4 |

| 5.3 | 4,1±0,11 | 6.8 |

| 5.33 | 4,1±0,11 | 7 |

| 5.5 | 4,3±0,11 | 7 |

| 5.7 | 4,4±0,11 | 7.4 |

| 6 | 4,7±0,12 | 7.6 |

| 6.5 | 5,1±0,13 | 8.2 |

| 6.99 | 5,5±0,14 | 8.8 |

| 7 | 5,5±0,14 | 8.8 |

| 7.5 | 5,9±0,15 | 9.4 |

| 8 | 6,3±0,16 | 10 |

| 8.4 | 6,97±0,1 | 10.78 |

| 8.5 | 6,7±0,17 | 10.7 |

| 9 | 7,1±0,18 | 11.3 |

| 9.5 | 7,5±0,19 | 11.8 |

| 10 | 7,9±0,2 | 12.4 |

| 10.5 | 8,2±0,21 | 13.3 |

| 11 | 9,13±0,1 | 14.08 |

| 11.5 | 9,55±0,1 | 14.69 |

| 12 | 9,4±0,24 | 15.1 |

| 12.5 | 10,38±0,1 | 15.92 |

| 13 | 10,2±0,26 | 16.2 |

| 13.5 | 11,21±0,1 | 17.15 |

| 14 | 11,62±0,1 | 17.77 |

| 14.5 | 12,04±0,1 | 18.38 |

| 15 | 11,8±0,3 | 18.6 |

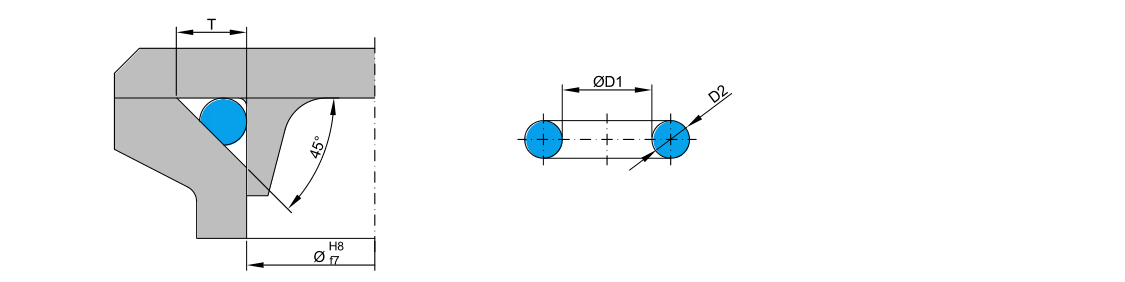

| D2 | T |

|---|---|

| 1 | 1,4±0,04 |

| 1.5 | 2,1±0,06 |

| 1.6 | 2,3±0,06 |

| 1.78 | 2,5±0,07 |

| 1.8 | 2,6±0,07 |

| 2 | 2,9±0,08 |

| 2.4 | 3,5±0,1 |

| 2.5 | 3,6±0,1 |

| 2.62 | 3,8±0,1 |

| 2.65 | 3,8±0,11 |

| 3 | 4,3±0,12 |

| 3.5 | 5,1±0,14 |

| 3.53 | 5,1±0,14 |

| 3.55 | 5,1±0,14 |

| 4 | 5,8±0,16 |

| 4.5 | 6,5±0,18 |

| 5 | 7,3±0,2 |

| 5.3 | 7,7±0,21 |

| 5.33 | 7,7±0,21 |

| 5.5 | 8±0,22 |

| 5.7 | 8,3±0,23 |

| 6 | 8,7±0,24 |

| 6.5 | 9,5±0,26 |

| 6.99 | 10,2±0,28 |

| 7 | 10,2±0,28 |

| 7.5 | 11±0,3 |

| 8 | 11,7±0,32 |

| 8.4 | 11,51±0,4 |

| 8.5 | 12,4±0,34 |

| 9 | 13,2±0,36 |

| 9.5 | 13,9±0,38 |

| 10 | 14,7±0,4 |

| 10.5 | 15,4±0,42 |

| 11 | 15,07±0,4 |

| 11.5 | 15,76±0,4 |

| 12 | 17,6±0,48 |

| 12.5 | 17,13±0,5 |

| 13 | 19,1±0,52 |

| 13.5 | 18,5±0,5 |

| 14 | 19,18±0,5 |

| 14.5 | 19,87±0,5 |

| 15 | 22,1±0,6 |

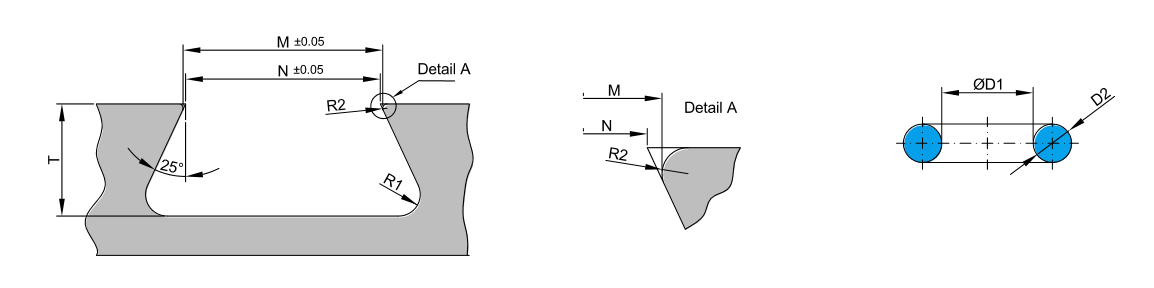

| D2 | T | N | M | R1 | R2 |

|---|---|---|---|---|---|

| 3.53 | 2,9±0,07 | 2.9 | 3.1 | 0.6 | 0.2 |

| 3.55 | 2,9±0,07 | 2.9 | 3.1 | 0.6 | 0.2 |

| 4 | 3,3±0,08 | 3.3 | 3.5 | 0.7 | 0.2 |

| 4.5 | 3,7±0,09 | 3.7 | 4 | 0.7 | 0.3 |

| 5 | 4,1±0,1 | 4.1 | 4.4 | 0.8 | 0.3 |

| 5.3 | 4,4±0,11 | 4.4 | 4.7 | 0.9 | 0.3 |

| 5.33 | 4,4±0,11 | 4.4 | 4.7 | 0.9 | 0.3 |

| 5.5 | 4,5±0,11 | 4.5 | 4.8 | 0.9 | 0.3 |

| 5.7 | 4,7±0,11 | 4.7 | 5 | 0.9 | 0.3 |

| 6 | 5±0,12 | 5 | 5.5 | 1 | 0.4 |

| 6.5 | 5,4±0,13 | 5.4 | 5.9 | 1.1 | 0.4 |

| 7 | 5,8±0,14 | 5.8 | 6.3 | 1.2 | 0.4 |

| 7.5 | 6,2±0,15 | 6.2 | 6.7 | 1.2 | 0.4 |

| 8 | 6,7±0,16 | 6.7 | 7.3 | 1.3 | 0.5 |

| 8.4 | 7,25±0,16 | 7.3 | 7.9 | 1.5 | 0.5 |

| 8.5 | 7,1±0,17 | 7.1 | 7.7 | 1.4 | 0.5 |

| 9 | 7,5±0,18 | 7.5 | 8.1 | 1.5 | 0.5 |

| 9.5 | 7,9±0,19 | 7.9 | 8.6 | 1.6 | 0.6 |

| 10 | 8,3±0,2 | 8.3 | 9 | 1.7 | 0.6 |

| D2 | T | B1 | Z |

|---|---|---|---|

| 1.5 | 1,3±0,03 | 1.8 | 1.2 |

| 1.78 | 1,5±0,04 | 2.2 | 1.5 |

| 1.8 | 1,5±0,07 | 2.5 | 2.1 |

| 2 | 1,5±0,08 | 2.8 | 2.6 |

| 2.4 | 1,8±0,1 | 3.4 | 3 |

| 2.5 | 1,9±0,1 | 3.4 | 3 |

| 2.62 | 2±0,1 | 3.6 | 3.1 |

| 2.65 | 2±0,11 | 3.7 | 3.2 |

| 3 | 2,3±0,12 | 4.1 | 3.5 |

| 3.5 | 2,7±0,14 | 4.7 | 3.9 |

| 3.53 | 2,7±0,14 | 4.8 | 4 |

| 3.55 | 2,7±0,14 | 4.8 | 4 |

| 4 | 3,1±0,16 | 5.4 | 4.5 |

| 4.5 | 3,5±0,18 | 6 | 4.9 |

| 5 | 3,9±0,2 | 6.6 | 5.4 |

| 5.3 | 4,1±0,21 | 7 | 5.8 |

| 5.33 | 4,1±0,21 | 7.1 | 6 |

| 5.5 | 4,3±0,22 | 7.2 | 6.1 |

| 5.7 | 4,4±0,23 | 7.6 | 6.3 |

| 6 | 4,7±0,24 | 7.8 | 6.4 |

| 6.5 | 5,1±0,26 | 8.4 | 6.8 |

| 6.99 | 5,5±0,28 | 9 | 7.2 |

| 7 | 5,5±0,28 | 9 | 7.3 |

| 7.5 | 5,9±0,3 | 9.7 | 7.7 |

| 8 | 6,3±0,32 | 10.3 | 8.2 |

| 8.4 | 6,4±0,32 | 10.4 | 8.3 |

| 8.5 | 6,7±0,34 | 10.9 | 8.7 |

| 9 | 7,1±0,36 | 11.6 | 9.2 |

| 9.5 | 7,5±0,38 | 12.2 | 9.6 |

| 10 | 7,9±0,4 | 12.8 | 10.1 |

| 10.5 | 8,2±0,42 | 13.6 | 11 |

| 11 | 8,6±0,43 | 14.1 | 11.3 |

| 11.5 | 9±0,46 | 14.7 | 11.8 |

| 12 | 9,4±0,48 | 15.5 | 12.4 |

| 12.5 | 9,8±0,5 | 16.1 | 12.8 |

| 13 | 10,2±0,52 | 16.7 | 13.3 |

| 13.5 | 10,6±0,54 | 17.3 | 13.8 |

| 14 | 11±0,56 | 17.9 | 14.2 |

| 14.5 | 11,4±0,58 | 18.5 | 14.7 |

| 15 | 11,8±0,6 | 19.1 | 15.1 |

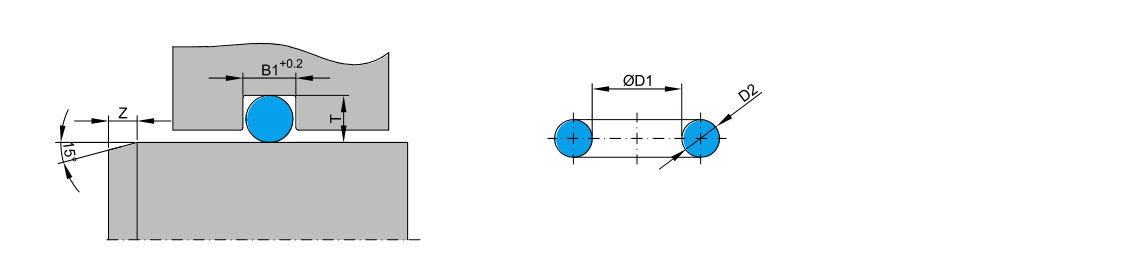

| D2 | T | B1 | Z |

|---|---|---|---|

| 1.78 | 1,6±0,04 | 2 | 1.2 |

| 1.8 | 1,6±0,04 | 2.1 | 1.2 |

| 2.4 | 2,2±0,05 | 2.7 | 1.3 |

| 2.62 | 2,4±0,05 | 2.9 | 1.4 |

| 2.65 | 2,4±0,05 | 3 | 1.5 |

| 3 | 2,8±0,06 | 3.2 | 1.5 |

| 3.53 | 3,3±0,07 | 3.9 | 1.9 |

| 3.55 | 3,3±0,07 | 3.9 | 1.9 |

| 5.3 | 4,9±0,11 | 5.7 | 2.4 |

| 5.33 | 4,9±0,11 | 5.8 | 2.6 |

| 5.7 | 5,3±0,11 | 6.1 | 2.8 |

| 6.99 | 6,5±0,14 | 7.4 | 3 |

| 7 | 6,5±0,14 | 7.4 | 3 |

| D2 | T | B1 | Z |

|---|---|---|---|

| 1.5 | 1,3±0,03 | 1.8 | 1.2 |

| 1.78 | 1,6±0,04 | 2 | 1.2 |

| 1.8 | 1,6±0,04 | 2.1 | 1.2 |

| 2 | 1,8±0,04 | 2.3 | 1.3 |

| 2.4 | 2,2±0,05 | 2.7 | 1.3 |

| 2.5 | 2,3±0,05 | 2.8 | 1.3 |

| 2.62 | 2,4±0,05 | 2.9 | 1.4 |

| 2.65 | 2,4±0,05 | 3 | 1.5 |

| 3 | 2,7±0,06 | 3.4 | 1.8 |

| 3.5 | 3,2±0,07 | 3.8 | 1.8 |

| 3.53 | 3,2±0,07 | 3.9 | 1.9 |

| 3.55 | 3,3±0,07 | 3.9 | 2 |

| 4 | 3,6±0,08 | 4.5 | 2.3 |

| 4.5 | 4,1±0,09 | 4.9 | 2.4 |

| 5 | 4,6±0,1 | 5.4 | 2.4 |

| 5.3 | 4,9±0,11 | 5.7 | 2.4 |

| 5.33 | 4,9±0,11 | 5.8 | 2.6 |

| 5.5 | 5±0,11 | 6 | 2.9 |

| 5.7 | 5,2±0,11 | 6.2 | 2.9 |

| 6 | 5,5±0,12 | 6.5 | 2.9 |

| 6.5 | 6±0,13 | 7 | 3 |

| 6.99 | 6,4±0,14 | 7.5 | 3.3 |

| 7 | 6,4±0,14 | 7.5 | 3.4 |

| 7.5 | 6,9±0,15 | 8 | 3.4 |

| 8 | 7,4±0,16 | 8.5 | 3.5 |

| 8.5 | 7,8±0,17 | 9.1 | 4 |

| 9 | 8,3±0,18 | 9.6 | 4 |

| 9.5 | 8,8±0,19 | 10.1 | 4 |

| 10 | 9,2±0,2 | 10.6 | 4.5 |

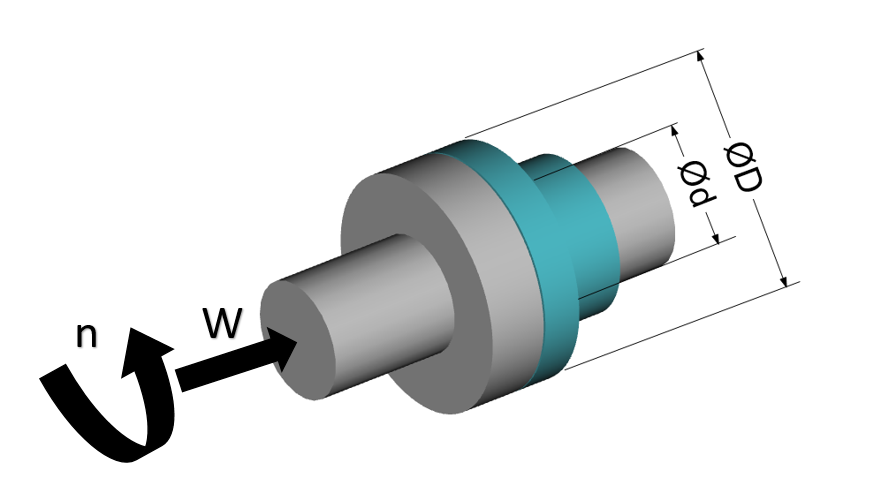

Static Sealing

Mean compression under pressure of 15-30%. Up to 1000 bar and more can be sealed. With pulsating pressures the hardness of the O-ring material should not be less than 80 Shore A.

| <16 MPa | 70 Shore A |

| >16 MPa | 90 Shore A |

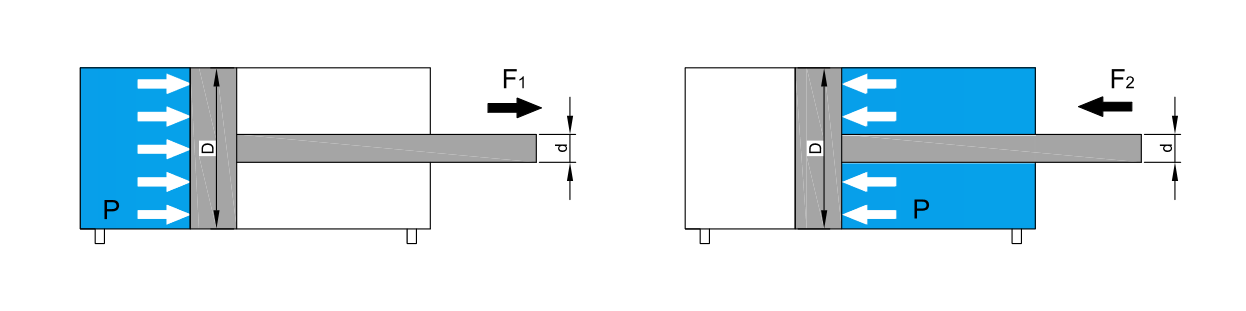

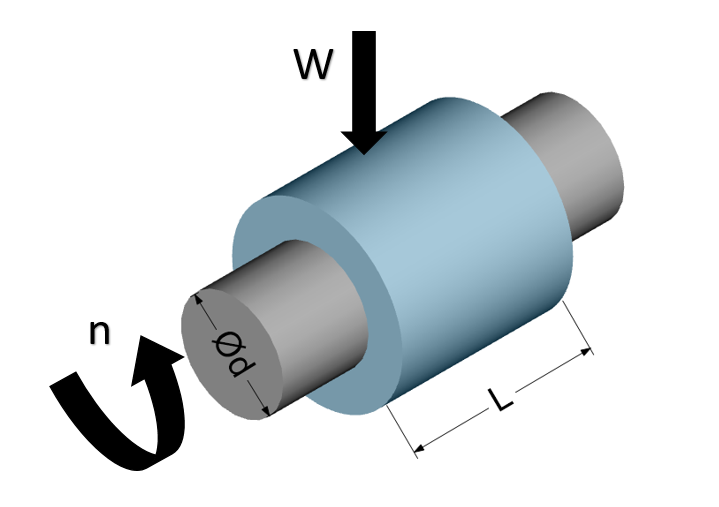

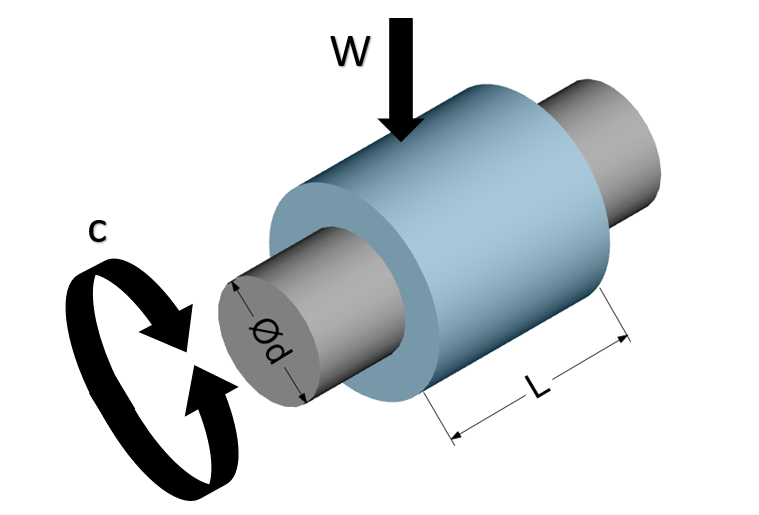

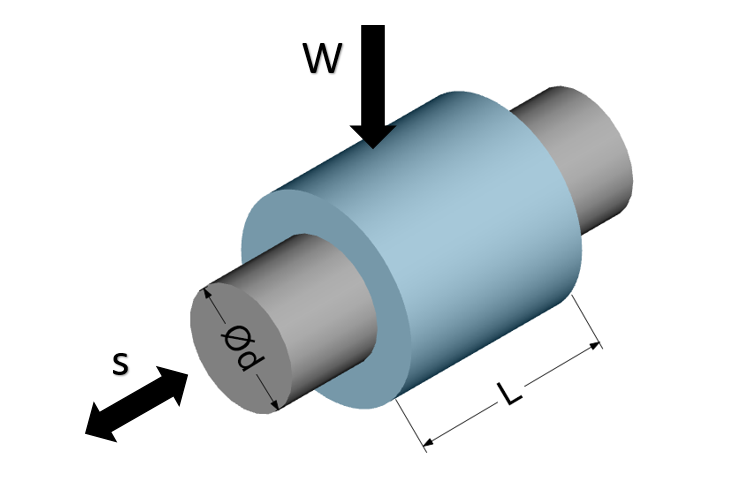

Dynamic Sealing

Due to the friction resistance, the deformation is minimised compared with static seals.

| < 6.3 MPa | 70 Shore A |

| > 6.3 MPa | 90 Shore A |

With hydraulic axial movement the minimum cross-section deformation should not exceed 6%.